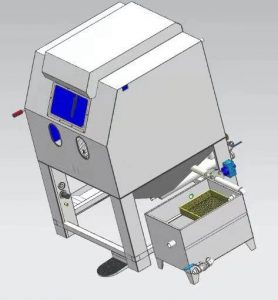

Vapor blaster also be named like: water sand blast machine, wet sandblaster, dustless blasting cabinet, dust free sandblaster

Compared with dry blasting, vapor blasting is a process of slurry sand and water together and spray to parts to get a perfect surface treating,In wet blasting, water-abrasive mixture is used resulting in smoother finish and less dust inside cabinet. Water washes away contaminants like grease and oil. In dry blasting these contaminants could cause coagulation of the abrasive and lead to machine failure. That is why wet blasting is often used nowadays for refurbishing parts such as motor and compressor parts.

Typical Advantage of vapor blasting

- Degreasing / surface finishing of components in the automotive, reconditioning & maintenance industries

- Cleaning of dies and molds

- Removal of paint, rust, scale, carbon & similar deposits in engineering industries

- Surface preparation prior to bonding, re-painting or re-coating

- Satin finishing of stainless steels & other special materials

- Cleaning of PCB’s & electrical connectors

- Removal of small burrs from manufactured components

JL vapor blasting machine is build of 2-3mm stainless steel, the ratio of water and sand can achieve 20:1.